Well Completion Info Tab

The Well Completion Info tab contains the basic information required to calculate completion costs and completion time for a well. For primary completions, this tab only appears when the Separate drilling from completion option is checked in the Well Details Tab; for recompletions, it is the only Info tab available.

Group: Wells may be added to Well Groups using this pane, either by including them in an existing group (selected from the dropdown list on the left) or by creating it with the Create button. When a group is selected the data is no longer editable in this tab but can be accessed via the corresponding Well Groups node (use the  Edit this group link). Conversely, use the Detach button to remove the well from the group and edit its details in this tab.

Edit this group link). Conversely, use the Detach button to remove the well from the group and edit its details in this tab.

- Rig: Select the rig that will perform the corresponding Well Completion job. Only if Extended Rig Mode is activated.

- Drilling Site: Select a Drilling Site where the completion will be performed. Use the button to load one from the list of already defined sites.

- Completion Time: Specify the time it will take the rig to perform this completion.

- Rig Cost Rate: Cost of rig usage per day.

- Completion Fixed Cost: Fixed expense of the well completion.

- Cost type: Choose between computing completion costs as CapEx or OpEx. When set to CapEx, the total completion CapEx = Completion Fixed Cost + Rig Cost Rate * Well Completion Time + CapEx of required Resources, with no associated OpEx. When set to OpEx, only resources will have associated CapEx, and all completion costs will be computed as OpEx.

Choose Cost Category: Choose a category for these costs (see Cost Categories).

Choose Cost Category: Choose a category for these costs (see Cost Categories).

Enable Production Lag: Set a lag between completion of the well and start of production.

Since the Enable Production Lag option refers to the time elapsed between completion of a well and start of production, it is available in the Well Drilling Info Tab only if drilling and completion for that well have not been separated; otherwise, it will only appear in the Well Completion Info tab.

Also, if the well belongs to a for which a production lag has not been enabled, the option will be hidden. (See Well Groups.)

Activities: Activities for the specific job of drilling or completing a well are defined separately in the node for each well. See Activities Pane for a full explanation of how activities work.

Resource Requirements: Resources required for the specific job of drilling or completing a well are defined separately in the node for each well. See Resource Requirements Pane for a full explanation of how resource tracking works.

Learning Curve (Completion)

Learning curves model the improvement in cost and time gained as a consequence of accumulated experience. The definition of a completion learning curve will imply a reduction in completion cost and time as more wells of similar characteristics are completed.

The default technique for learning to take place consists in grouping wells in Completion Info Groups. Wells belonging to the a group where a learning curve has been defined will learn from all wells belonging to the same group that have already been completed.

Alternatively, the Use global experience option may be checked to let wells learn from all other wells already completed in the project.

- Linear: Defines a linear reduction in well cost and time.

- Fixed Cost Start Well / End Well: Well count when the cost learning curve starts/ends. All previous wells will have the initial cost.

- Completion Time Start Well / End Well: Well count when the completion time learning curve starts/ends. All previous wells will have the initial completion time.

- Fixed Cost % Change: Percentage change from start to end of cost learning curve (note that a negative number should be entered).

- Completion Time % Change: Percentage change from start to end of drilling time learning curve (note that a negative number should be entered).

.PNG)

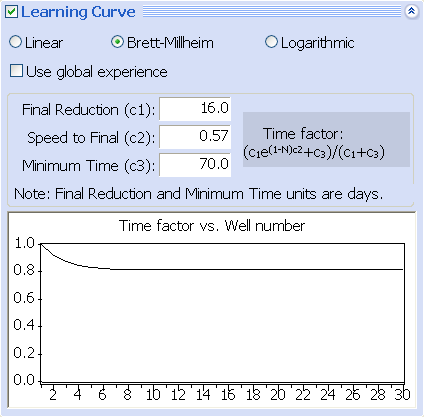

- Brett-Millheim: Defines a reduction well cost and time based on empirical data. J.F. Brett and K.K. Millheim have developed a drilling performance curve based on actual field data. Their model requires three parameters:

- Final Reduction (c1): Total reduction in completion time.

- Speed to Final (c3): Rate of learning.

- Minimum Time (c3): Minimum achievable completion time.

The graph displays drilling days per well vs. well count (Brett and Millheim 1986![]() Brett, J.F. and K.K. Millheim, “The Drilling Performance Curve: A Yardstick for Judging Drilling Performance”, SPE 15362.).

Brett, J.F. and K.K. Millheim, “The Drilling Performance Curve: A Yardstick for Judging Drilling Performance”, SPE 15362.).

- Logarithmic: Defines a logarithmic reduction in well completion cost and time.

- Completion Time Experience Base: Well count when the completion time learning curve starts. All previous wells will have the initial completion time.

- Completion Time Learning Rate: Logarithmic learning slope for completion time.

- Fixed Cost Experience Base: Well count when the fixed cost learning curve starts. All previous wells will have the initial fixed cost.

- Fixed Cost Learning Rate: Logarithmic learning slope for fixed cost.

The logarithmic learning curve is calculated using the formula c0∙λlog2(v/v0) where C0 is the initial value (time or cost), λ is the learning rate, V0 is the experience base and V is the completion number currently being performed. See further in Understanding Logarithmic Learning.

.PNG)